We build structures and artifacts in composite fibers

G.Composites, with the support of an expert and harmonized team, since years operates in the composites materials’ market and continues the evolution of its activity with increasing engagement for the benefits of clients.

Accepting that the prime asset of a company is the staff, there is heavy investment in both time and money in developing their expertise.

In keeping with the times the company is computerized throughout.

The system in place encompasses the management of telematic programming, all administrative tasks, orders, invoicing etc., in order to satisfy the increasing demands of the client base.

Equally it maintains the maximum flexibility and reliability, essential elements for the sector in which the company operates.

Key qualities of G.Composites are the agility and professionalism of it’s “Gruppo di Lavoro”, always ready to solve the technical problems put before them.

In short G.Composites is recognized in the market place as a leading edge company in the composites materials’ sector.

Production is carried out using the latest and appropriate technology.

The technology used by G.Composites in the manufacture of products in GRP (Glass Fiber Reinforced Plastics) are:

HLU – Hand Lay up – Stratification by hand

SU – Spray up – Simultaneous projection

RTM - Resin transfer moulding – Injection such as:

- Direct Injection

- Low Pressure Injection

- Assisted Vacuum Injection

G.Composites works in the following sectors:

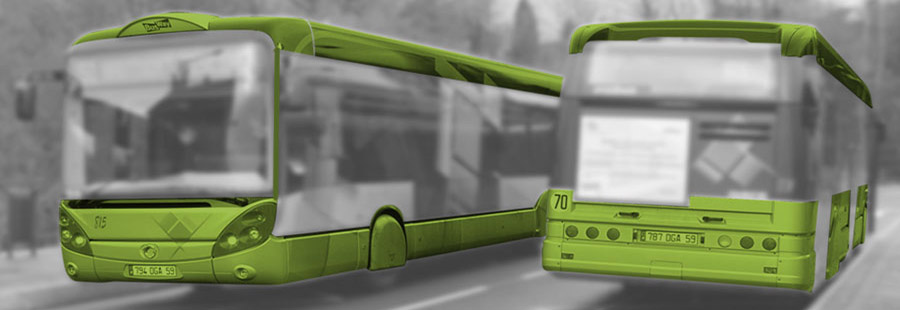

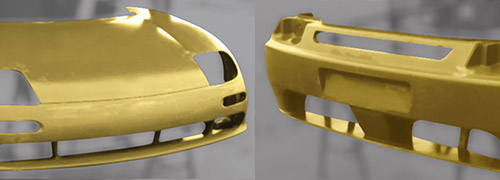

Transport: microcar, supercar, bus

Special transport: firefighting, civil protection, defense, tankers of various short and sizes

Ecology: protective cases of various types

Construction: crash paneling

Naval: fittings

Railways: fittings

Other: fittings, sanitary, technical lighting.

The feature of G.Composites is that of finishing “combined” products with parts other than their own molding. Involving a series of often complex finishing process, assembly of the parts, Post Curing treatment, treatment of the surfaces such as priming, painting and finishing.

It studies and controls the various components required for the demands of the product.

It studies and finishes the assembly jig in order that the parts in question have the precision and reliability demanded by the product.

We are a “partner” to our client and our role is to resolve all the inherent problems in the product they wish to carry out.

We assist our client throughout the project, examining its feasibility and suggesting the best cost effective solutions to meet the requirements of the finished article.

Production is overseen in all its phases, with quality control as set out in the Certification. Production is programmed and controlled with additional finishing from working patterns.

G.Composites is attentive to all innovations with the aim of the constant improvement of the product:

• Prime materials

• Structural adhesives

• Equipment

• Logistics and packaging

• Care of the environment